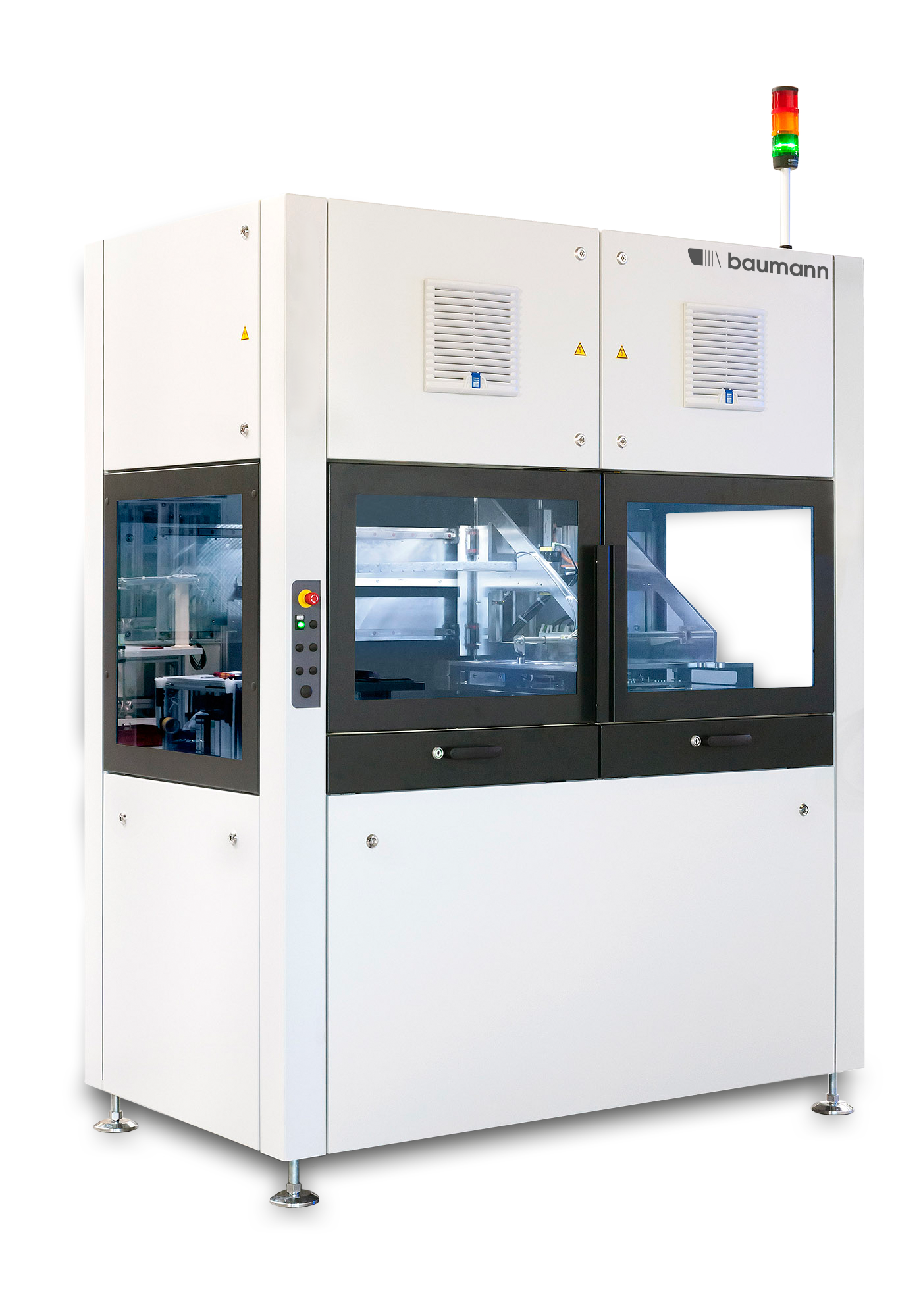

BAUMANN rout|box

depaneling of PCBs using an end mill

There are three versions of the rout|box (offline, inline, integrated).

The

PCB depaneling is done with a milling tool. The fixing of the panel

works from above with a clamping device. A 60,000 rpm milling spindle

runs on a high-precision triple-axis servo drive system beneath the

PCBs.

The individual PCBs are clamped in position during the milling process by grippers and then – depending on the rout|box version – discharged individually or as a group. Coded variant sets enable quick and simple product changeover. The machine recognises the current set and selects the corresponding milling program automatically. The milling tool diameter is checked at the same time.

Product features:

- Efficient extraction for minimal residual particles

- Ethernet interfaces for connecting peripheral equipment and host PCs (MES)

- Extremely user friendly thanks the mobile touch-panel

- Automatic milling tool changeover

- Monitoring of milling tool crack

- Simple product changeover due to coded variant sets

- Robust cell concept in accordance with the proven Baumann standard

PCB formats

- PCB length 460 mm

- PCB width 460 (230) mm

- PCB thickness 0.4 bis 3.2 mm

- Max. PCB weight (panel) 10 kg

- Max. PCB weight (PCB) 2 kg

- Component height at spindle side 18 mm

- Component height at gripper side 40 mm

Technical

data

- Axis speeds: up to 1,000 mm/s

- Positioning accuracy: ± 0.01 mm

- Repeat accuracy: ± 0.003 mm depending on handling

- Cutting speed: up to 1.6 m/min

- Milling tool speed: up to 60,000 rpm

- Cutting accuracy: ± 0.10 mm with Vision System, ± 0.15 mm without Vision System

- Milling tool: from below

- Noise level: 69 db (A)