power electronics

PCBs, hybrid singulation and testing

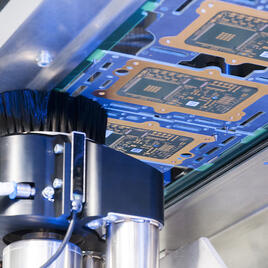

Panels are often the preferred manufacturing method in the semi-conductor industry. When producing PCBs and circuits on ceramic boards (DBC, DCB, LTCC, HTCC), the individual PCBs are depanelled after the assembly process.

Baumann is a specialist in the field of singulating ceramic PCBs. Baumann’s break|box provides a standardised and partially patented solution for both methods – laser perforation at the top or the bottom.

Baumann offers customers two effective solutions in the field of conventional PCB depaneling. Firstly, the newly developed rout|box, die mit einem Fingerfräser die Platinen aus ihrem Nutzen herausfräst. Die Fräsbahnen sind in diesem Fall frei programmierbar. Zum anderen existiert die bereits bekannte de|box, which utilises the so-called "V-Cut procedure", i.e. a pair of opposing separating blades.

All the versions can be implemented either as a stand-alone cell or be integrated as modules into Baumann robot cells.

Application examples

High power test

Baumann offers standard systems for testing power electronics, from low to high power. The dynamic, static or insulation measurement tests can be carried out at room temperature as well as at operating temperatures of up to 175°C.

Test adapter

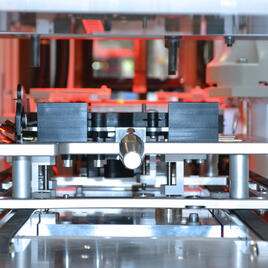

When it comes to testing power electronics, such as IGBTs for electromobility, Baumann offers product-specific test adapters for dynamic, static or insulation measurement tests.

Singulation of ceramic

break|box - Automated solutions for the singulation of DBC, LTCC, DSH, HTCC, etc., including solutions for optical and electrical tests.

PCB singulation

rout|box - PCB depanelling uses an end mill. The individual PCBs are clamped in position during the milling process by grippers and then discharged individually or as a group.

ISO and EOL test

power|box - our standard cell for isolation and EOL testing of

power electronics. Special feature: EOL test with integrated water supply, space-saving

and compact.

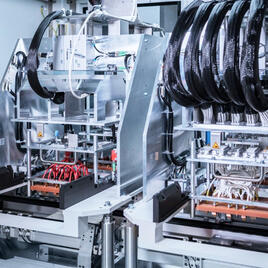

Inverter assembly / Inverter test

Numerous special manufacturing processes, such as press-fit and dispensing, demand the assembly of an inverter. From testing individual components during assembly to complete assembly test.

Baumann in the electronics and telecommunications industries

Baumann has been supplying manufacturers in the electronics and telecommunications industries with assembly systems for more than 20 years. Time is often the decisive factor for market success and reliable quality in this fast-moving industry with its short innovation cycles and wide range of products.

Together with our customers, we develop tailor-made solutions to ensure flexible and cost-effective production process which keep pace with rapidly changing products.

Standardised platforms enable us to react to product and process changes and thus provide our customers with a competitive edge.

Our proven test systems provide supporting documentation and quality assurance for almost all areas of the electronics industry.

Baumann offers everything from a single source:

- Final assembly systems from a single cell up to a complete line

- from LCIA (low cost intelligent automation)

- to quantity-dependent semi-automated solutions

- and robot-supported fully automated solutions.

Baumann solutions and technologies for customers from the electronics and telecommunications industries

Baumann Automation assembly systems are used worldwide to successfully produce a wide range of electronic components. Our systems cover the widest range of process steps.