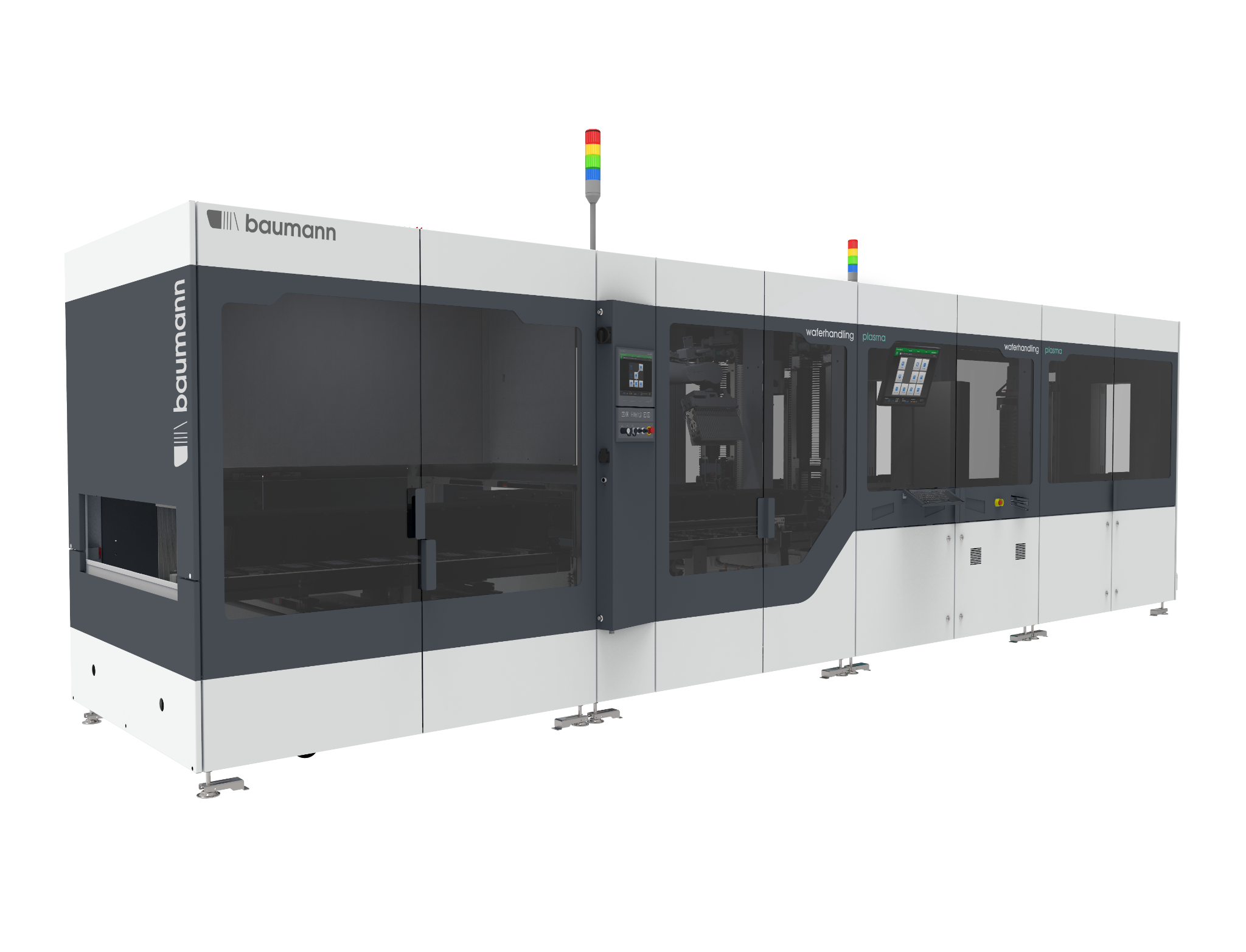

Wafer handling plasma – 3rd generation

Loading and unloading of graphite boats

To enhance the efficiency of solar cells, they are coated with an

anti-reflective film. This layer is applied using a special technique

called PECVD (see below).

During the batch process, a graphite boat is loaded with wafers and transported into a furnace.

Baumann wafer handling plasma ...

... fully automates the

loading and unloading process and uses specially developed gripper

technology that guarantees safe handling with minimum wafer breakage.

A 6-axis robot integrated into the system enables complex loading and unloading procedures with maximum precision.

An optional integrated vision system checks for material defects and monitors coating quality after unloading.

Main characteristics:

- Throughput of up to 5700 w/h

- Breakage rate ≤ 0.1%

- Technical availability ≥ 98%

PECVD is the abbreviation for plasma-enhanced chemical vapour deposition, or plasma-assisted chemical vapour deposition (PACVD).